Electric Airplane Battery Manufacturers

Listing Category by product

“Leading Electric Airplane Battery Manufacturers: Pioneering the future of sustainable aviation”

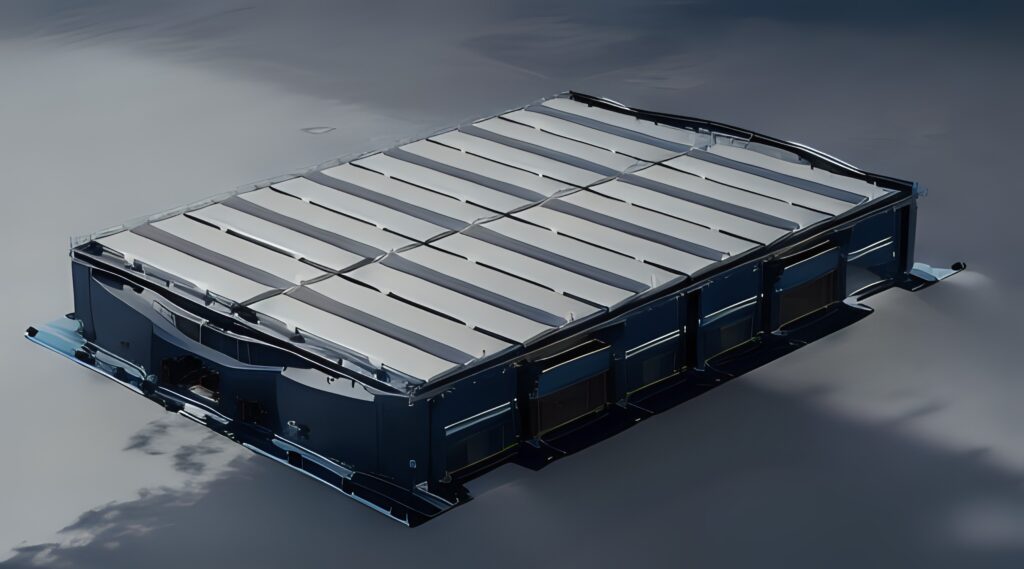

Electric airplane batteries are essential for the future of sustainable aviation. These batteries power electric propulsion systems, offering a cleaner alternative to traditional jet engines by reducing emissions and noise. Manufacturers are focused on enhancing battery efficiency, safety, and performance.

Key features of Electric Airplane Batteries

- Battery chemistry: Electric airplane batteries primarily use lithium-ion (Li-ion) or lithium-polymer (LiPo) technology. These batteries are lightweight, reliable, and offer high energy density, which is crucial for efficient flight.

- Energy density: A higher energy density allows electric airplanes to fly longer distances and carry heavier loads. This is a key factor for extending the range of electric aircraft.

- Capacity: Battery capacity, measured in kilowatt-hours (kWh), determines how far the airplane can fly on a single charge. Larger capacities allow for longer flights and better endurance.

- Safety: Safety is a top priority. Manufacturers integrate advanced systems to prevent issues like overheating, fires, or battery failures, ensuring the reliability of electric aircraft.

- Charging: Electric airplane batteries can be charged using standard electrical outlets or faster charging systems. Ongoing advancements in charging technology are reducing charging times and improving efficiency.

- Weight: Battery weight plays a significant role in the aircraft’s overall performance. Manufacturers are working to balance energy density with weight to maximize flight efficiency.

- Regulations: Electric airplane batteries must comply with strict aviation regulations set by authorities like the FAA (Federal Aviation Administration) and EASA (European Union Aviation Safety Agency) to ensure safety and airworthiness.

Electric airplane batteries are key to advancing sustainable aviation. Continued innovation and improvements in battery technology are paving the way for cleaner, more efficient air travel.